|

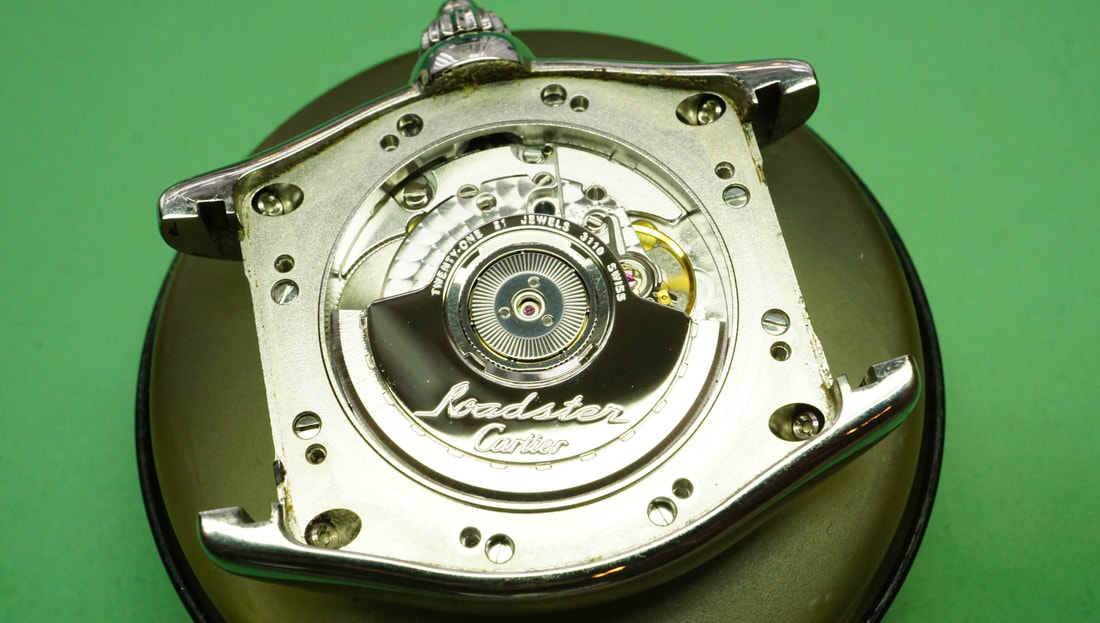

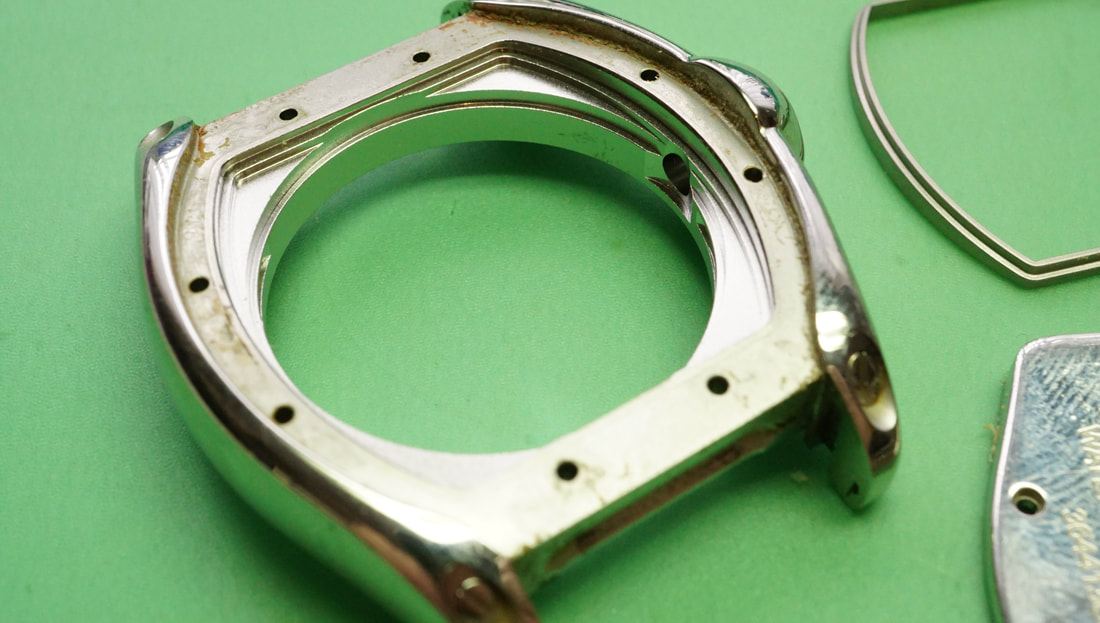

It been a while since my last post so thought id share a recent straight forward piece with you readers. Today's quick post is having a look over the Cartier Roadster which features an ETA 2892-2 movement that is very popular with Swiss brands. The movement is much akin to the older 2824 but slightly thinner and in my opinion slightly better in many respects, the choice of this movement is very common among many Swiss brands as it allows various and ambitious case designs. The casing has seen better days and is in need of some love, fortunately the bracelet is relatively simple and the only part which has two finish types ( polished & brushed ). We start as always with breaking the watch down and cleaning the watch part by part, since the 2892 is relatively simple i have spared the breakdown of the movement this time. As can be seen above the casing breaks down into many parts, eight screws for the case back and a further eight to hold the front bezel. The movement can be seen here with a polished rotor and perlage finish, always nice to see during service even if it invisible to the owner during use. The main case parts minus the screws can be seen here, also visible is a fair amount of grime which builds up over the years, a simple ultrasonic clean will remove the stubborn dirt in prep for polishing. Looking below you will see how dirt can bypass even the smallest gaps and sit for years building up. Once any casing or bracelet is clean it is important to re finish them in the correct order, in this instance the watch is all steel but with a brush and polish finished bracelet, the brushing must be done first with polishing done after to prevent scratching the final finish. Once a satisfactory brush finish is obtained the bracelet is cleaned and dried again before taping off the brushed parts with Kapton Polymide tape in preparation for polishing. Polishing is a process which can be both long or short depending on need, it is a broader subject than i will discuss here but it can involve many stages with lots of cleaning in between stages for superior results. Despite the original condition this watch only need two stages to remove the scratches and final stage to high lustre. With good knowledge and careful planning any watch case can be improved without destroying the original lines and features, taking time to stop and clean between each stage is vital for the best end result. Going in harsh with high grit abrasives may well remove the scratches but along with it you will remove the shape of the original design.

Watch cases should only be polished/buffed/brushed at the request of the customer, the practice of polishing is frowned upon by many but it is the customer who ultimately decides what is desired. In the end this watch was finished and i think you'd agree the result is pleasing and original to the way it should look :)

0 Comments

|

Archives

July 2021

Categories |