|

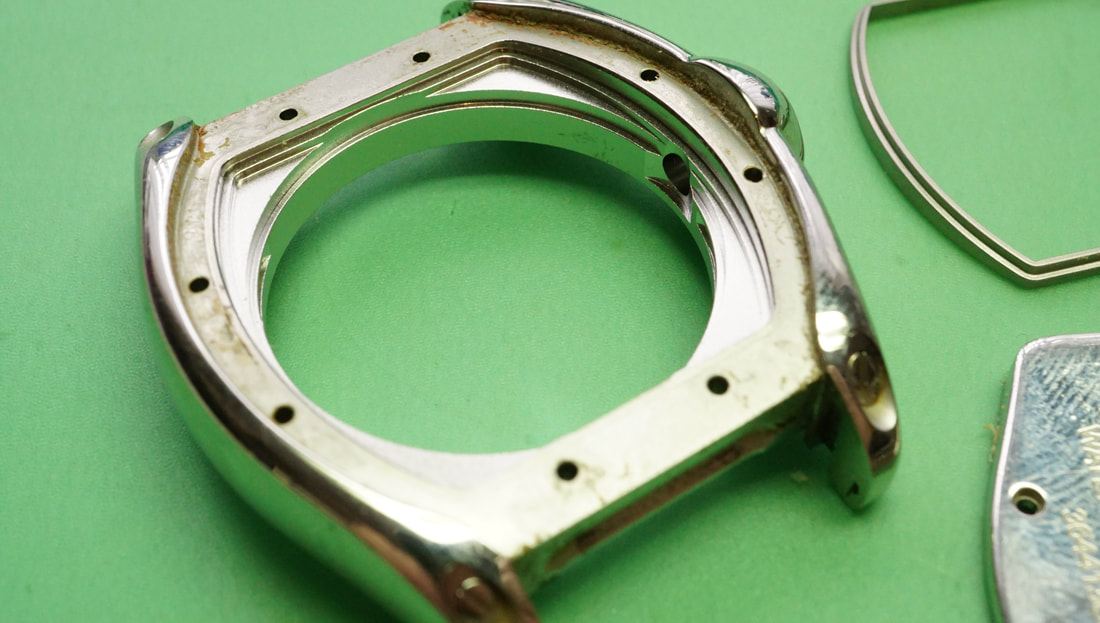

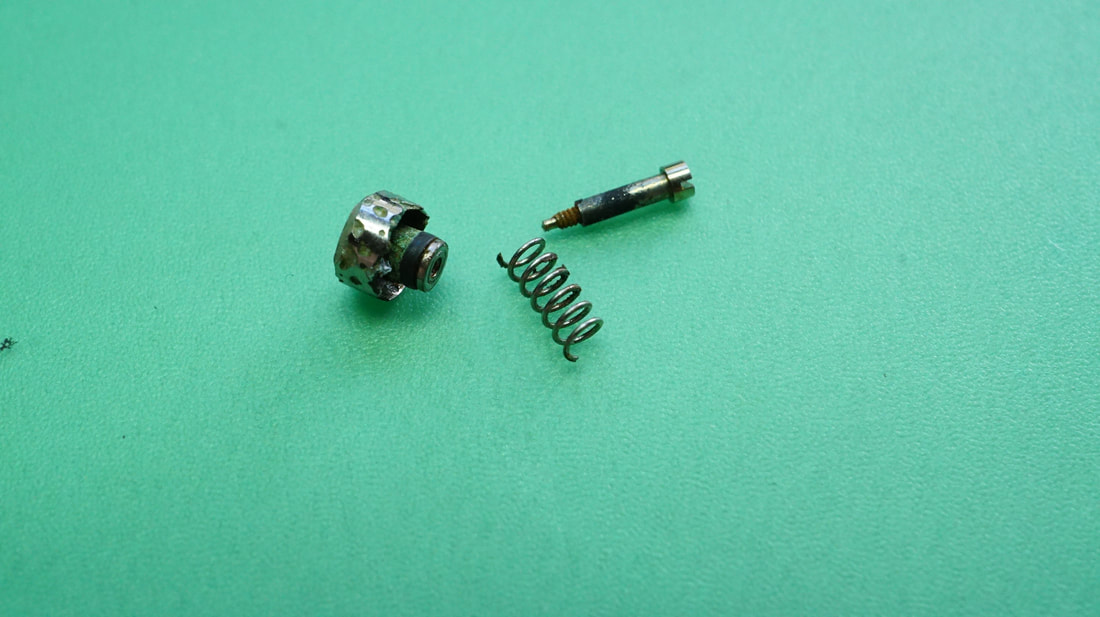

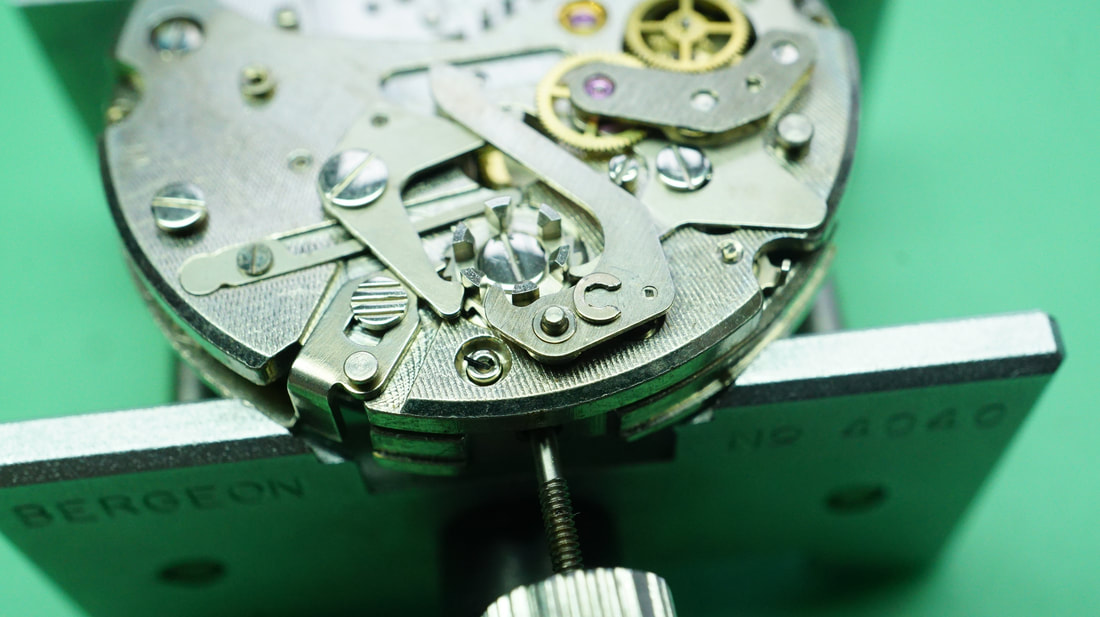

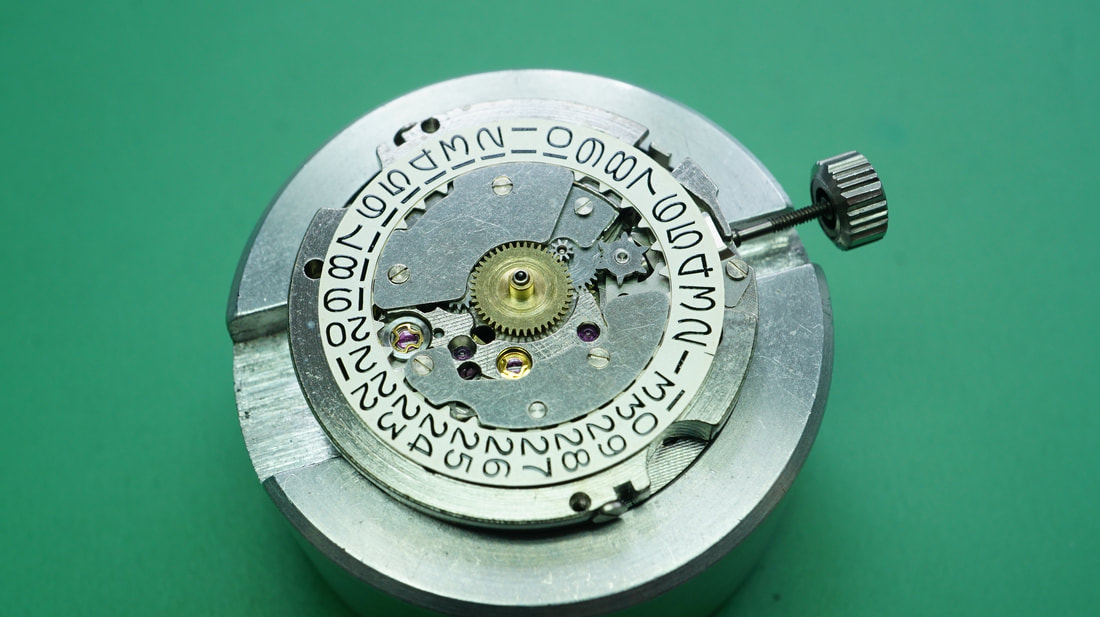

Well its been a very long time since my last post here, the demand for watch repairs has increased so much since the last i wrote that the inevitable " i'll do it tomorrow " line has been well and truly used up. But today i'm back and back with a juicy classic reverse Panda Aquaplunge, the lesser seen version of the Aquaplunge line up. The chronograph version of the Aquaplunge uses the Landeron calibre 149, based on the previous iterations of the Cal 48 the 149 was produced between 1937-1970 and in no small amount of approx 3.5 million units with many parts often interchangeable with other related calibres. The version in this particular watch is rose plated, although more akin to a copper colour similar to that of Omega movements. In this instance the casing is a little grubby as to be expected with years of use, the movement is mainly solid with some rust in places, nothing that can't be sorted out. The dial is in pretty good shape and the hands have a nice natural patina to match, notice the arrow recorder hand and the diamond tip of the chrono hand. No bracelet as the customer supplied this watch ( along with many others ) as a watch head only, but my pick would likely be some sort of shark mesh bracelet. Below you will find a short array of disassembly photos, obviously in some cases I have to shorten the sequence but you'll get the general idea. These types of chronographs all work in a very similar way with only a few exceptions, quite enjoyable to work on for the most part but not without some flaws. With the movement assembled and running sweetly the only cosmetic work to complete would be a new glass, cleaning out & re lubing the pushers, and a general ultrasonic clean. The casing cold have been polished and bezel re-painted & lumed but it would have lost some of that retro charm that makes it cool. All in all a really pleasing watch, enjoyable to work on and a visual feast, i'm gonna miss this beauty when she's gone but i always have the photos for nostalgia. Til next time, take care & have fun :)

0 Comments

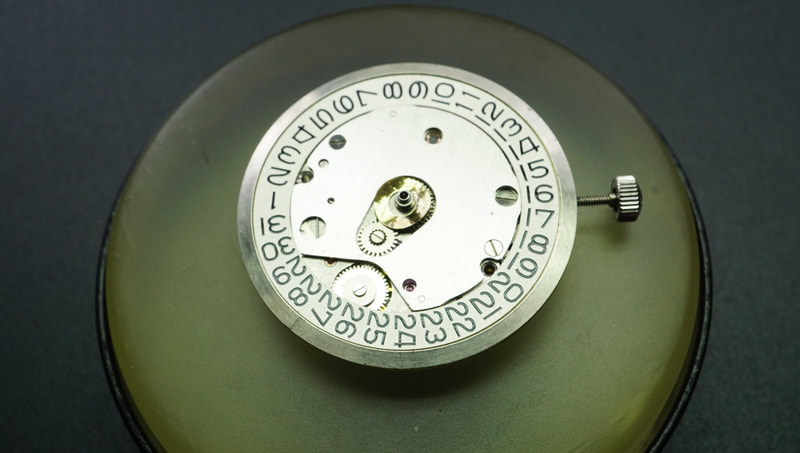

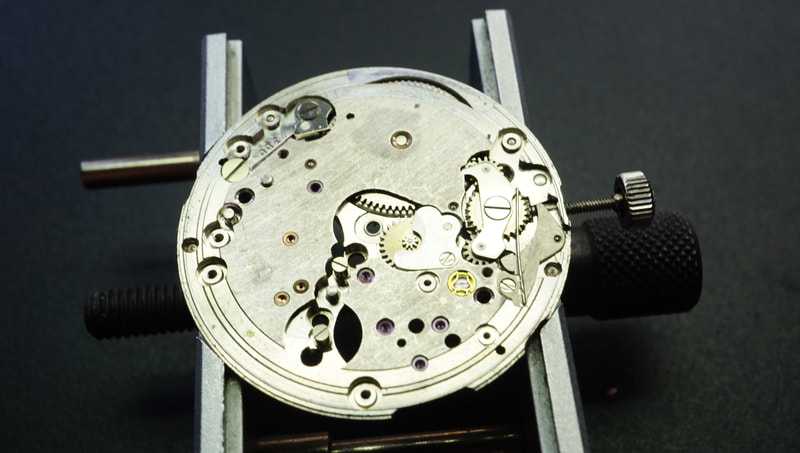

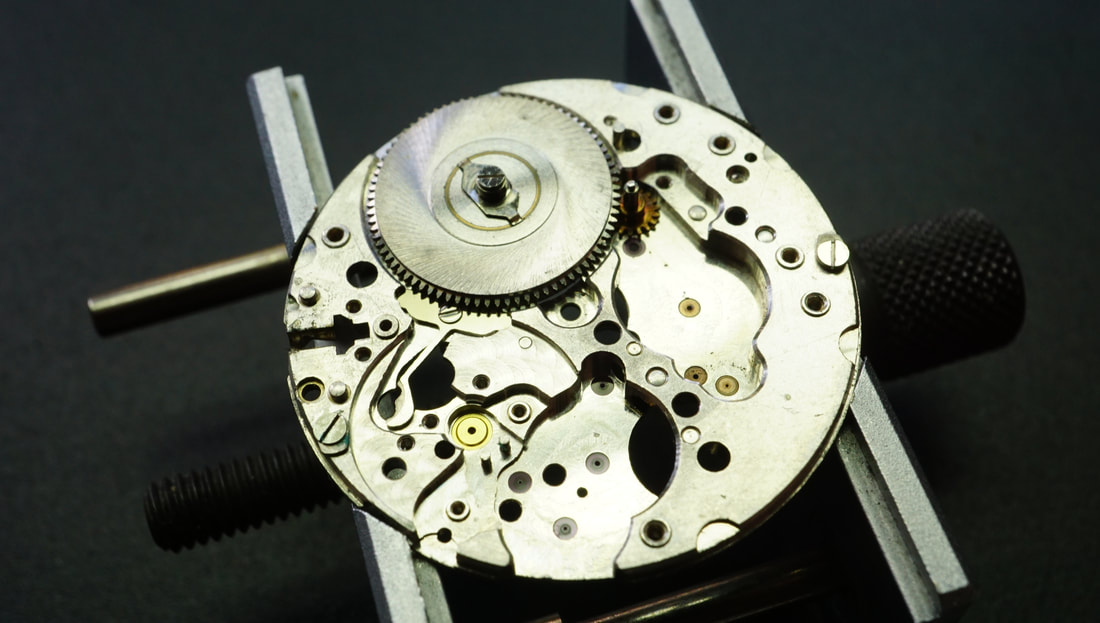

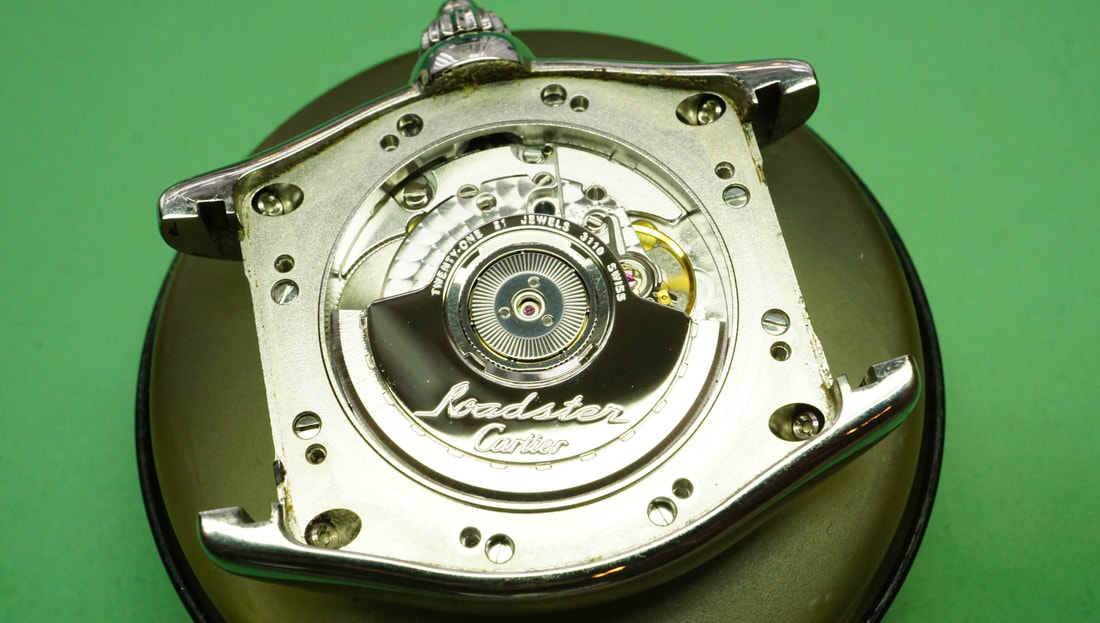

It never ceases to amaze me how something complex can hide behind something so simple, this Longine's Flagship is just such one of those things, so today we look into this watch in all its glory. While this watch is not the most complex in terms of features or complications where it does excel is in its construction and use of both old and new methods within the individual systems. Its worth noting that this watch was produced in a time where machinery was not as advanced as today's, i think even in today's era the design would still be costly to produce but lets look at that further down the list. The case back has now lost the original green & blue enamel infill but given the age this is fairly common to see, similar situation with Grand Seiko;s which no doubt some of you have seen. The whole movement, dial , and hands are in very good condition throughout, simple design that is timeless and can still be found on modern remakes of Longine's watches. The date disc on the upper plate is held down only by an outer ring which is purely friction fit, a light lift is enough to remove this and progress with the dial side. Visible in the bottom left photo we can see the use of an older rocker style bar that was more commonly found in earlier wrist watches, older but still a system that works well. Turning over to the movement side we can see the rotor removed and with very little in way of parts to it, this allows the rotor to spin freely under kinetic force with minimal drag from other components. The Rotor and ring gear are formed as one piece and held only by a single small axle to the upper plate. With the movement powered down and train bridge removed we can now see the rotor driving wheel as well as gear train. In the lower of the image you can see the use of the setting lever spring which is located in the middle of the inner main plate rather than dial side as would normally be found. The use of the rocker bar and the modern setting lever spring is a great system employing both older techniques and more modern parts in the same system. In the middle of the upper images we can see the reversing gear and driving wheel which allow the rotor to wind the mainspring as well as freely manually winding of the movement. Also visible is the center wheel which in this movement is mounted to its own bridge/cock and secure by two screws from the dial side, see the closer image below > Back on the dial side the motion work and date parts are removed, despite the busy look of the dial side the construction is kept as simple as possible using only what is needed to perform the task. The complexity lies in the manufacturing of the main plate and all the cut outs but we shall get to that in a moment. With the movement stripped down it is then cleaned and later inspected before assembly. The above image shows the mainspring & barrel which is marked on the under side as " DO NOT OPEN " as is often found on Longine's watches. These sealed barrels ideally do need cleaning and re greasing but if a spare is not available then it may be best to leave alone, spares for this movement are like hens teeth so the best efforts are made before assembly. With the movement all clean the re assembly was relatively straight forward, the above images are during assembly but not always in order :) The initial timing before adjustment was quite good but of course the watch needs time to settle before adjusting. Although i have serviced thousands of watches ive never come across this calibre before and it has quite surprised me ( in a good way ). The use of old and new is quite unique and most of the watch movement design is quite simple but mostly efficient, the complexity is subtle and can be seen if you look closely at the level of detail in the main plate. The watch main plate has been painfully and carefully cut out, holes drilled and various end mill cuts taken to produce a very intricate but simple design, the shear cost to produce this part must have been very high and even today would not be easy to make. Given the design and complex nature of it's manufacture it is beyond any doubt and reason as to why some watches cost as much as they do, although this watch can be found for relatively small sums these days its true value is much greater. Overall this has been a great watch to work on, in fact its been an education, as just when you think you've seen it all there's always something new. This watch like so many will go on to be with a new owner and hopefully be enjoyed as much as it should be, the simple exterior hiding the otherwise more complicated machine inside. If you enjoyed this blog or any of the others then don't forget to share with your friends :) The next blog may be over with our friends over at Waha Watches but i will be sure to put a link up somewhere for yall !! It been a while since my last post so thought id share a recent straight forward piece with you readers. Today's quick post is having a look over the Cartier Roadster which features an ETA 2892-2 movement that is very popular with Swiss brands. The movement is much akin to the older 2824 but slightly thinner and in my opinion slightly better in many respects, the choice of this movement is very common among many Swiss brands as it allows various and ambitious case designs. The casing has seen better days and is in need of some love, fortunately the bracelet is relatively simple and the only part which has two finish types ( polished & brushed ). We start as always with breaking the watch down and cleaning the watch part by part, since the 2892 is relatively simple i have spared the breakdown of the movement this time. As can be seen above the casing breaks down into many parts, eight screws for the case back and a further eight to hold the front bezel. The movement can be seen here with a polished rotor and perlage finish, always nice to see during service even if it invisible to the owner during use. The main case parts minus the screws can be seen here, also visible is a fair amount of grime which builds up over the years, a simple ultrasonic clean will remove the stubborn dirt in prep for polishing. Looking below you will see how dirt can bypass even the smallest gaps and sit for years building up. Once any casing or bracelet is clean it is important to re finish them in the correct order, in this instance the watch is all steel but with a brush and polish finished bracelet, the brushing must be done first with polishing done after to prevent scratching the final finish. Once a satisfactory brush finish is obtained the bracelet is cleaned and dried again before taping off the brushed parts with Kapton Polymide tape in preparation for polishing. Polishing is a process which can be both long or short depending on need, it is a broader subject than i will discuss here but it can involve many stages with lots of cleaning in between stages for superior results. Despite the original condition this watch only need two stages to remove the scratches and final stage to high lustre. With good knowledge and careful planning any watch case can be improved without destroying the original lines and features, taking time to stop and clean between each stage is vital for the best end result. Going in harsh with high grit abrasives may well remove the scratches but along with it you will remove the shape of the original design.

Watch cases should only be polished/buffed/brushed at the request of the customer, the practice of polishing is frowned upon by many but it is the customer who ultimately decides what is desired. In the end this watch was finished and i think you'd agree the result is pleasing and original to the way it should look :) Well this blog was well overdue and apologies for those that follow me for such a delay, its been a mad past few months with ever increasing demands for watch repair ! So today we finally have a close up look at one of Seiko's only mono pusher vintage chronographs, if your an avid Seiko collector then no doubt this is one of the holy grail watches you would want in your collection. The watch in general was in good condition but was in need of servicing and some cosmetic light touches, the only major drawback being that the pusher has rotten and although functional it muddies the otherwise good looks when seen up close. So lets not dilly dally and get into the meat of it >> After many emails and searching i was not successful in finding a new pusher, as with many old Seikos there simply lacks the spares available and those that do exist are hoarded by watchmakers like precious gold. The watch would have to be continued with original pusher, functional if a little flea bitten ( big fleas of course ). Moving on to the movement it should always be noted to take great care when removing a chronograph center hand as on some movements they can be staked on with good force and hard to remove normally, breaking a center hand is the last thing you would want. The center hand should always be supported as much as possible when lifting so as the tube can be lifted evenly and with gentle/gradual pressure, the hour & minute hands can come off after but never the other way. With exception to the above C clip the movement was other wise sound, the clip had come loose over time and use so would need tightening as spares are non existent. For those who want to see all photos feel free to browse through the gallery below. With the movement done it was time to turn attention to the bezel, with so little original paint remaining the only option would be to remove whats left and start again. Patience is your friend here and taking time pays dividends if your willing to put in the effort. The depth of the numerals is very shallow so proves quite a challenge but patience and a steady hand can help :) With the movement complete and the casing cleaned up the watch was ready to be fully assembled, a new glass and a very light polish ( not buff ) the watch was then fitted with an original bracelet and ready to go. Absolute pleasure working on this and probably never see another again, quite sad they don't make them like this anymore. The ugly pusher aside this watch i think represents what is truly great about Seiko and about watch collecting in general, simple & functional with classic styling. This watch will be heading its way back to owner ready for selling, if your interested then pay morningtonwatches.com a visit as it is available but who knows for how long ! Seiko 1965 - Model 5717-8990 - Morningtonwatches.com With so much work to be done of late, writing up blogs can take up valuable time but i will try to not to leave it so late next time :) |

Archives

July 2021

Categories |